Understanding the Essentials and Applications of Plastic Extrusion in Modern Manufacturing

In the world of modern-day production, the strategy of plastic extrusion plays an instrumental role. Unraveling the fundamentals of this process reveals the true convenience and capacity of plastic extrusion.

The Principles of Plastic Extrusion Refine

While it may appear complex, the basics of the plastic extrusion process are based upon fairly uncomplicated concepts. It is a production process wherein plastic is melted and after that shaped into a continuous profile via a die. The raw plastic material, commonly in the form of pellets, is fed into an extruder. Inside the extruder, the plastic goes through warm and pressure, creating it to thaw. The liquified plastic is after that required via a designed opening, referred to as a die, to create a long, continuous product. The extruded item is cooled and after that cut to the wanted size. The plastic extrusion process is thoroughly utilized in numerous markets because of its flexibility, performance, and cost-effectiveness.

Various Kinds of Plastic Extrusion Strategies

Structure upon the standard understanding of the plastic extrusion procedure, it is needed to check out the numerous strategies associated with this manufacturing method. The 2 primary methods are profile extrusion and sheet extrusion. In profile extrusion, plastic is thawed and formed right into a continual account, often made use of to create pipelines, rods, rails, and home window frameworks. In contrast, sheet extrusion produces large, flat sheets of plastic, which are normally more processed into items such as food packaging, shower curtains, and automobile parts. Each method needs specialized equipment and specific control over temperature and pressure to ensure the plastic preserves its shape throughout air conditioning. Understanding these methods is key to making use of plastic extrusion efficiently in modern-day manufacturing.

The Function of Plastic Extrusion in the Automotive Market

An overwhelming majority of parts in modern vehicles are items of the plastic extrusion process. This procedure has actually transformed the vehicle market, transforming it into an extra effective, economical, and flexible production market. Plastic extrusion is primarily utilized in the production of various auto components such as bumpers, grills, door panels, and control panel trim. The process provides an uniform, consistent result, making it possible for producers to produce high-volume get rid of excellent accuracy and marginal waste. The agility of the extruded plastic components adds to the general decrease in vehicle weight, enhancing gas efficiency. The longevity and resistance of these components to warm, cold, and impact enhance the long life of cars. Thus, plastic extrusion plays a critical duty in automotive production.

Applications of Plastic Extrusion in Customer Item Manufacturing

Beyond its considerable influence on the vehicle industry, plastic extrusion verifies similarly effective in the world of customer goods manufacturing. The versatility directory of plastic extrusion enables producers to design and generate complex forms and dimensions with high accuracy and performance. The versatility, versatility, and cost-effectiveness of plastic extrusion make it a preferred find out this here option for several customer goods suppliers, adding dramatically to the market's development and advancement.

Environmental Impact and Sustainability in Plastic Extrusion

The prevalent use of plastic extrusion in manufacturing invites scrutiny of its environmental effects. As a process that often utilizes non-biodegradable materials, the environmental effect can be significant. Energy usage, waste manufacturing, and carbon discharges are all problems. Nonetheless, sector innovations are raising sustainability. Reliable machinery reduces energy use, while waste administration systems reuse scrap plastic, lowering raw product demands. Additionally, the growth of naturally degradable plastics offers a more environmentally friendly alternative. Regardless of these enhancements, even more innovation is needed to alleviate the ecological impact of plastic extrusion. As culture leans in the direction of sustainability, makers have to adjust to stay feasible, emphasizing the importance of constant research study and development in this area.

Final thought

In final thought, plastic extrusion plays a critical duty in contemporary production, especially in the auto and customer products sectors. Comprehending the essentials of this process is crucial to enhancing its advantages and applications.

The plastic extrusion procedure is thoroughly used in Visit Website numerous sectors due to its efficiency, flexibility, and cost-effectiveness.

Structure upon the basic understanding of the plastic extrusion procedure, it is required to check out the numerous techniques included in this production method. plastic extrusion. In contrast, sheet extrusion creates big, level sheets of plastic, which are generally more refined right into items such as food product packaging, shower curtains, and automobile parts.An overwhelming bulk of parts in modern vehicles are items of the plastic extrusion process

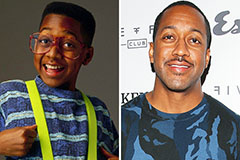

Jaleel White Then & Now!

Jaleel White Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!